Other equipment

Corrugate filling

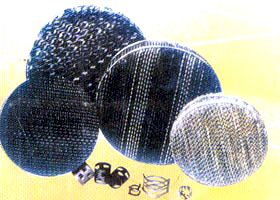

Under the guidance of Shanghai Research Institute of chemical industry, our factory specializes in the production of new efficient corrugated structured packing and bulk packing, which can be made of stainless steel, copper, aluminum, pure titanium, molybdenum titanium and other materials. It has been widely used in spices, pesticides, fine chemicals, petrochemical and other fields.

Structured fillers are divided into mesh, mesh, orifice plate, calendered orifice plate, etc. The bulk packing mainly includes: metal ball ring packing, metal stepped ring packing and metal ring rectangular saddle, namely metal Anglo packing.

Table of geometrical characteristic parameters of products

Geometric characteristic parameters of SW type mesh corrugated packing

| Packing model | Texture of material |

Peak height hmm |

Specific surface area m2/m3 |

Hydraulic diameter ah mm |

Tilt angle |

Void fraction % |

F factor m/s kg/m2 |

Theoretical tray No/m |

Pressure drop dmmHG/m |

| SW-1 | Stainless steel | 4.5 | 643 | 5.7 | 45° | 91.6 | 1.4-2.2 | 6-8 | 2-3.5 |

| SW-2 | 6.5 | 450 | 9 | 30° | 95.5 | 1.5 | 4-5 | 1.6-1.8 |

Geometric characteristic parameters of corrugated mesh packingSC=CY SB=BX

| Packing model | Texture of material |

Peak height hmm |

Specific surface area m2/m3 |

Hydraulic diameter ah mm |

Tilt angle |

Void fraction % |

F factor F m/s kg/m2 |

Theoretical tray No/m |

Pressure drop mmHG/M |

| CY | stainless steel | 4.3 | 700 | 5 | 45° | 87-90 | 1.3-2.4 | 6-9 | 5 |

| BX | 6.3 | 500 | 7.3 | 30° | 95 | 2-2.4 | 4-5 | 1.5 |

Geometric characteristic parameters of orifice corrugated packing

| model | texture of material |

Peak height hmm |

Specific surface area m2/m3 |

Hydraulic diameter ah mm |

Tilt angle |

Void fraction % |

F factor F m/s kg/m2 |

Theoretical tray No/m |

Pressure drop mmHG/m |

| SM125 | stainless steel | 24 | 125 | 35 | 45° | 98.5 | 3 | 1-1.2 | 1.5 |

| SM225 | 12 | 250 | 15.8 | 45° | 97 | 2.6 | 2-3 | 1.5-2 | |

| SM325 | 8 | 350 | 12 | 45° | 95 | 2 | 3.5-4 | 1.5 | |

| SM425 | 6.5 | 450 | 9 | 45° | 93 | 1.5 | 3-1 | 1.8 |

Geometric characteristic parameters of corrugated packing for rolled orifice plate

| model | texture of material |

Theoretical tray No/m |

Peak height hmm |

Void fraction % |

Specific surface area m2/m3 |

Pressure drop mmHG/M |

F factor m/s kg/m2 |

| 700y | stainless steel | 5-7 | 4.3 | 85 | 700 | 7 | 1.6 |

| 500x | 3-4 | 6.3 | 90 | 500 | 2 | 2.1 | |

| 250y | 2.5-3 | 97 | 250 | 2.25 | 2.6 |

Geometric characteristic parameters of metal ball ring

| Model, nominal size | Outer diameter, height and thickness |

Number of piles n/m3 |

Accumulation weight rp kg/m3 |

Specific surface area a m2/m3 |

Void fraction % |

Dry fill factor a/m-1 |

| Dg16 | 16×16×0.8 | 143000 | 216 | 239 | 0.928 | 299 |

| Dg25 | 25×25×0.5 | 55900 | 427 | 219 | 0.934 | 269 |

| Dg38 | 38×38×0.6 | 13000 | 365 | 129 | 0.945 | 153 |

| Dg50 | 50×50×1 | 6500 | 395 | 112.3 | 0.949 | 131 |

| Dg76 | 76×76×1.2 | 1860 | 313 | 0.95 |